|

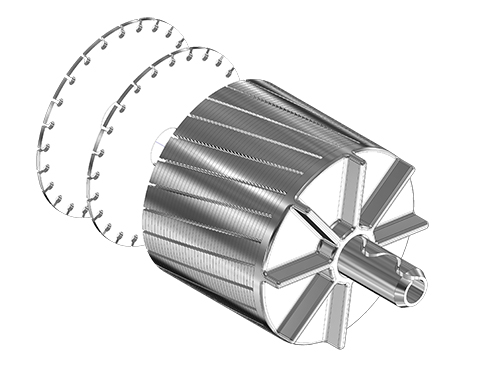

In the production of die cast rotors, a ground CONNEX Spring Pin is used to stack rotor plates holding the grooves of the stack at the correct angle. The stack is then put into a die casting mold. After molding, the CONNEX Spring Pin is pressed out. The rotor bore has the necessary close tolerance and requires no further treatment. Despite the abrasive nature of the transformer plate, the CONNEX Spring Pin can be reused many times. It adapts itself elastically to the diameter of the bore.

|

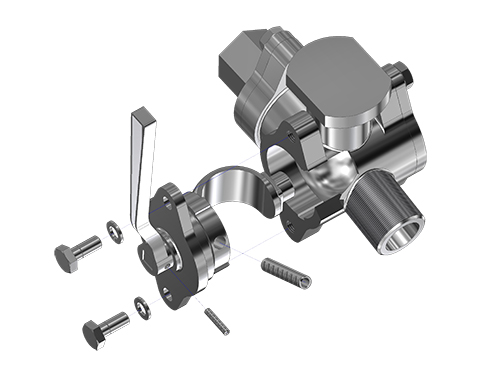

A CONNEX Heavy Spring Pin is used as a stop for the 90 degree turn of the pivoting core in a pneumatic shutoff valve. The high seating capacity of the pin is the reason it was selected for this application and is why the valve handle is secured with a CONNEX Spring Pin.

|

|

CONNEX Heavy Spring Pins are used in operating rods for roller shutters and venetian blinds. The change in the direction of turn places alternate shear stress on the pins, which requires them to have the high seating capacity CONNEX Heavy Spring Pins have.

|

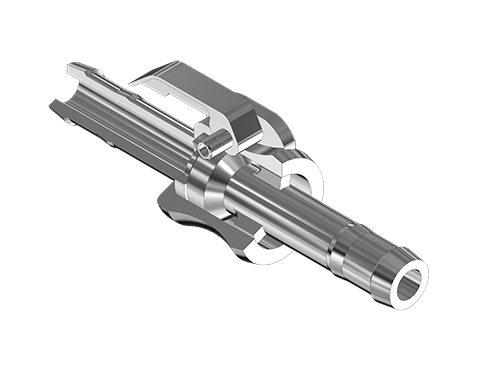

The conventional solution intended a straight-slotted pin as the axles for the eccentric fastener. Incorrect insertion of the straight-slotted pin resulted in a peeling effect in the bore of the fastener handle. After extended use, the fastener became faulty and resulted in expensive stoppage time for the machine. The CONNEX Spring Pin solves that problem easily without changing the design.

|